What methods can be used to maintain lubrication oil quantity and quality?

For oil bath lubrication, quantity of oil can always be adjusted by adding oil to maintain the manufacturer’s recommended level. However, another approach to maintain the proper quantity of oil is with bearing housing seals. When properly applied, bearing seals can eliminate lubrication leaks from the housing and help maintain recommended oil levels.

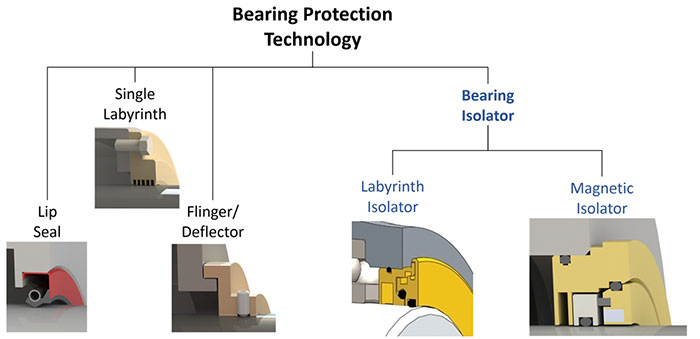

Image 1. Common bearing housing seals (Images courtesy of Hydraulic Institute)

Image 1. Common bearing housing seals (Images courtesy of Hydraulic Institute)Examples are lip seals, labyrinth isolators and magnetic face seals shown in Image 1. These mentioned seals are also useful in the reduction of oil contamination to maintain the quality of the oil.

Particle contamination can be avoided with consideration of materials, design and maintenance of lubricant containers, seals and bearing isolators. When selecting gaskets and seals, materials should be compatible with the lubricant.

When filling the bearing housing, the fill port should be cleaned prior to opening, the lubricant container should be closed until filling, and care should be taken to prevent atmospheric contaminants from entering the fill port during the fill process.

In addition to preventing lubricant leakage, bearing housing seals also serve to prevent contaminant ingress.

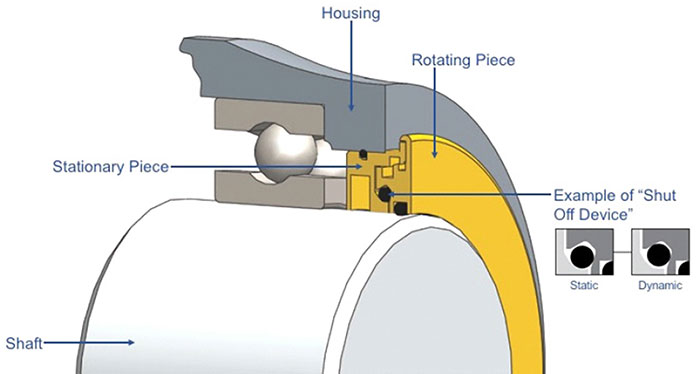

Focusing on isolator technology, labyrinth and magnetic face-type bearing isolators are widely used on pumps. Bearing isolators allow increased pressure created in the bearing housing by normal pump operation to vent through the isolator and have proven to be effective at reducing, and sometimes eliminating, contaminant ingress.

The face design and the labyrinth design allow for the venting to occur while in operation.

The face design of the magnetic isolator protects the bearings against contaminants while the pump is shut off or in standby using the contacting faces.

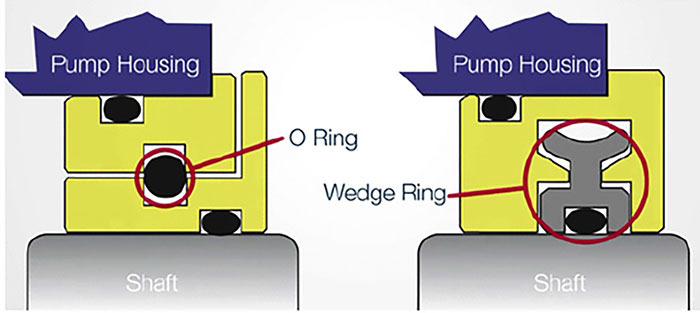

Image 2. Two examples of shut-off devices used in labyrinth seals.

Image 2. Two examples of shut-off devices used in labyrinth seals.Labyrinth isolators may use shut-off features to provide ingress protection when the equipment stops rotating, as shown in Image 2.

These shut-off devices are designed to prevent moisture from penetrating the bearing chamber when the equipment shuts down and air is drawn into the housing.

When properly specified, bearing housing lubrication quality-enhancing components—including oilers, bearing protection devices and vents—can be effective in maintaining the quality of bearing lubricants.

For more information about proper bearing lubrication and maintaining the quality of the lubrication, download HI’s new free white paper “Proper Lubrication Methods for Bearings” at www.pumps.org/lubrication.