Pumps are the heart of fluid-transfer operations. Unexpected failure can devastate production and profits. Operators in the industrial-manufacturing realm have been looking for ways to see into the future, to know when, how and why a pump will need to be serviced before a catastrophic breakdown will bring the production process to a halt.

Over the years, manufacturers have worked to improve pump reliability and have developed tools to monitor pump performance and health. Sometimes these tools result in little more than a “check engine light” scenario. There is a problem, so what is the next step?

Evolving technology allows the pump and driving motor to be monitored around the clock via continuous cloud connectivity. This article illustrates how the technology works and how it can optimize pump performance, reliability, and cost of operation and maintenance.

Image 1. A predictive-monitoring system can identify failure modes and provide actionable repair guidance, monitoring the pump and motor 24/7 with Wi-Fi or cellular access. (Images courtesy of Griswold, part of PSG)

Image 1. A predictive-monitoring system can identify failure modes and provide actionable repair guidance, monitoring the pump and motor 24/7 with Wi-Fi or cellular access. (Images courtesy of Griswold, part of PSG)The Challenge

In most industrial production and processing plants, unexpected failures can be devastating to the production schedule and, by extension, the operator’s bottom line. There are many negatives associated with pump failures:

- disrupted production

- batch failures

- excessive downtime

- costly repairs

- costs for new parts and shipping

- costs for service calls, which can include overtime

- lost or compromised revenue

In many cases, failure can be prevented if the pump is installed and operated correctly. At the very least, operators should ensure that the pump is properly aligned, operating without cavitation, has properly lubricated bearings, sufficient baseplate rigidity and more. Getting these wrong will lead to costly—and preventable—repairs.

When a pump failure occurs, replacing the broken component alone may not be sufficient. Getting to the root cause can also be difficult and time consuming for plant staff.

If a mechanical seal fails, for example, simply replacing it may not prevent a repeat failure if there is a shaft vibration issue that should be resolved. Pinpointing a root cause can lead to hours of if/then assumptions and trial and error, along with the chasing of symptoms that may ultimately require a level of expertise that can only be provided by a third-party source.

Furthermore, if the pump is in a remote location, the level of complexity is ratcheted up. In these installations, it is difficult to monitor the pump without a technician at the site, which brings its own added costs and safety issues.

Current Industry Solutions

Facilities have focused on deploying predictive maintenance (PdM) techniques as a solution to increasing production reliability since the 1990s. In the pump industry, PdM uses techniques such as vibration and temperature monitoring to observe a pump’s performance and health during operation. Early on, PdM was a manual process where measurements were taken by hand-held devices, then documented and analyzed. This process relied on vibration experts to interpret the data.

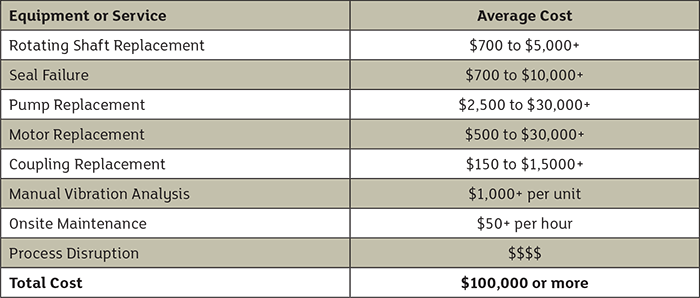

Table 1. Average cost chart

Table 1. Average cost chartThe pump industry has taken steps to deploy advanced technology in PdM as a way to automate the process.

While some current technologies have automated the data collection, they still may have limitations:

- Complete machine monitoring. Most technologies are designed to monitor the pump only, even though the pump is only part of the machine.

- Not true remote monitoring. The majority of “remote” monitoring technologies require technicians to be within Bluetooth range of the pump with a mobile device to accurately gather the data.

- No real-time data. Due to the remote-monitoring restrictions, this eliminates real-time data, as well as 24/7 monitoring.

- Alarm only. The data collected by other diagnostic technologies is equivalent to an alert only with no clear level of urgency.

- No repair guidance. While there is an alert to signify a problem, the root cause is not identified nor any repair guidance offered.

- No single-source data collection. It is cumbersome to collect the data on all machines within the plant in one easy-to-reference and accessible location.

The Solution

There are predictive monitoring systems that can identify failure modes and provide actionable repair guidance, monitoring the pump and motor around the clock with Wi-Fi or cellular access.

Two sensors are installed on the pump, and two are installed on the motor. The sensors work in unison to predict the health of the pump and motor. This capability allows a diagnostic reading and analysis of a number of performance parameters for the pump, motor, coupling and foundation, including:

- Tri-axial vibration reading: The equipment’s vibration signature produces details regarding its health and can be used to identify impending bearing failure, misalignment, cavitation levels,

pipe strain and more. - Temperature reading: Elevated operational temperatures are a sure indication of upcoming bearing failure, inadequate bearing lubrication and other causes of issues. Studying temperature trends can help the operator detect thermal-fault signatures, which will provide additional insight into when potential breakdowns may occur.

- Electromagnetic reading: Sensors are able to monitor the motor’s true revolutions per minute (rpm) and proactively diagnose electrical faults through the electromagnetic tools.

This data is collected, compiled and transferred to the cloud to be analyzed, using the full capabilities of the industrial internet of things (IIoT). The data is analyzed by a series of machine-learning algorithms that can determine the overall health level of the pump and motor, define the root cause of any alerts and generate steps to resolve the issue.

When a potential issue is identified, the monitoring system will notify the operator via an automated email report, identifying the level of alert (whether it needs to be handled immediately or it is something to be aware of), the root cause, as well as actionable resolution guidance. The system can identify more than 20 failure modes. Such failure modes include bearing failure, coupling misalignment, cavitation, foundation looseness and others.

Field Reliability

A system was installed on a new ANSI centrifugal pump that used a chilled water loop for a steel-coating company. Upon installation, the maintenance team completed a startup checklist. The pump was put into service and sensors immediately identified two issues: misalignment and foundation looseness. The cause of foundation looseness was identified as a loose foundation bolt. The maintenance team rechecked alignment with a laser alignment tool and found there indeed was an issue.

After correcting these, the pump began operating acceptably. If these issues had not been caught in the early stages, the pump would have failed prematurely.

After operating acceptably for 11 months, a new alert was identified. Sensors identified an electrical fault in the motor that would lead to motor failure. The end user was alerted of this fault and was able to replace the motor before a complete failure occurred.

Conclusion

New technologies take existing pump diagnostic capabilities and create a holistic way of looking at the pump and motor. The capabilities help optimize system uptime while increasing equipment life span and operational safety.

This will result in fewer accidents that can have a negative impact on site personnel and the surrounding environment, while simultaneously meeting the demanding needs of production schedules and quotas, efficiency, maintenance, repair and replacement costs, spare-parts inventory and revenue optimization.