Oil-free reciprocating gas compressors help facilitate compliance and reduce emissions.

Pumps

In the process industries—water, wastewater, oil and gas, food and beverage, chemical processing, mining, building services, pulp and paper—pumps are ubiquitous. The pumps used in those industries vary widely and each requires expert handling. These articles provide information on selecting the right pump for the application, as well as testing and troubleshooting, installation and maintenance on those pumps.

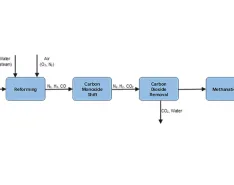

How these are meeting the demands of the oil and gas industry.

Examining the potential of hydrogen and green energy.

Engineers must place safety and efficiency at the forefront, especially when it comes to drinking water.

Desalination is projected to increase as a source of drinking water in the coming years.

Adopting pretreatment techniques may lower costs overall.

Enhancing efficiency and reliability by rebuilding a pivotal pump.

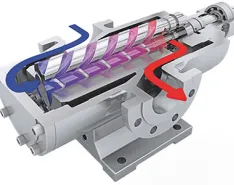

Axial piston pump technology helps to save energy and costs.

Concerns surrounding upcoming PFAS regulations and the differences between PAC and GAC.

The criteria needed to select the proper prepackaged, submersible pump station.

This maintenance technique is making it increasingly simple to pinpoint issues.

McGrath serves as the vice president of sales for Nidec.