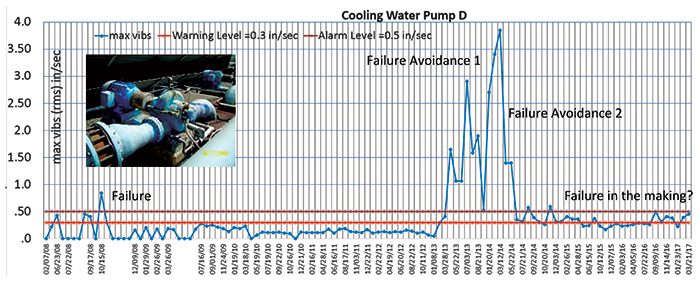

In my June 2016 Pumps & Systems column (read it here), I presented the results of vibration-trending analysis of six cooling water pumps over the course of eight years. Many readers were surprised the plant had few actual failures despite continual, elevated vibration levels. Bearing housing vibrations exceeding 0.3 in/sec (velocity, RMS) have reached the warning level, and over 0.5 in/sec have reached alarm level.

There is little data to determine when such badly vibrating pumps would fail: today, next month or within the year. Because of this, plants tend to rely on a few common strategies. The first approach is to pull the pump as soon as vibrations are over the alarm (or warning) level. These plants would rather spend money on (perhaps too-frequent) overhauls rather than experience catastrophic failure. The second approach is to allow the pump to fail and either repair or replace it. With no time for proactive measures, the plant pays a higher cost when the pump does crash.

Figure 1. Vibrations tracking to avoid failures (Courtesy of the author)

Figure 1. Vibrations tracking to avoid failures (Courtesy of the author)We obtained data from an eight-year study to illustrate how long a double-suction horizontally split pump in distress can remain operational, even with excessive vibrations. Figure 1 shows monthly vibration trends over eight years for one of these six pumps. (Note: Zero values mean the pump was not operational during the data route due to some operational constraints. This downtime was not critical to the data gathered due to the extended length of the study.)

Pump D operated at elevated vibrations between February 2008 and November 2008, when the outboard pump bearing failed catastrophically. The plant decided to adopt a strategy to take future action after a pump maintained elevated vibrations for six months. The next such occurrence took place in March 2013, and the following September the pump outboard bearing was replaced on-site.

Unfortunately, no other attention was given to the unit (alignment, etc.), and thus it resumed a high vibration trend soon after the pump bearing change. The plant replaced the bearings again about six months later (May 2014). This time, however, better care was taken to realign the pump to the motor, significantly reducing vibration levels. The “six-month” rule appears to have worked for this plant, allowing proactive maintenance on the pump at the usual planned outage periods.

It must be emphasized that the “six-month” rule may be only applicable for the type of pumps monitored in this study. Other pump types may or may not follow the same rule. Axial flow turbine pumps, for example, would not survive for six months at such elevated vibration levels. It might only take a few weeks for a different type pump to fail, and monthly monitoring intervals may not detect the upcoming issue soon enough. For those cases, on-line live pumps reliability and efficiency monitoring system (PREMS) 2A should be used for continual monitoring would be a proper approach. Our next objective is to apply PREMS to high energy pumps installation for a study to correlate reliability (vibrations) with energy (efficiency). We aim to assess not only imminent failures and economics of prevention, but also economics of efficiency degradation and methods to rectify these issues. For those interested in participating in such a study, please contact me with questions and ideas.

There is a note “Failure in the making?” on Figure 1, although the vibrations, given the history, do not suggest that. Can you think of the reason why? The best answer(s) will be published in the follow-up column(s) on this topic.