Q. What methods are recommended for measuring a controlled-volume metering pump's flow rate, and what should be taken into account to ensure an accurate measurement?

A. The following methods can be used to measure flow rate for a controlled-volume metering pump.

1. Rate-of-flow measurement by weight: Measurement of rate of flow by weight depends on the accuracy of the scales used and the accuracy of the measurement of time. A certification of scale calibration should be part of the test record, or, in the absence of certification, the scales should be calibrated with standard weights before or after the test. Time intervals for the collection period must be measured to an accuracy of one-quarter of 1 percent.

2. Rate-of-flow measurement by volume: This method involves measuring the change in the volume of a tank or reservoir during a measured period of time. The tank or reservoir can be positioned on the inlet or discharge side of the pump as long as all flow into or out of the tank or reservoir passes through the pump. When establishing reservoir volume by linear measurements, users should consider the geometric regularity (flatness, parallelism, roundness, etc.) of the reservoir surfaces as well as dimensional changes resulting from thermal expansion or contraction, or distortion resulting from hydrostatic pressure of the liquid. Liquid levels should be measured using hook gauges, floats, and vertical or inclined gauge glasses. Under some circumstances, evaporation and loss of liquid by spray may be significant and have a greater effect than thermal expansion or contraction. Users should either allow for such loss or prevent the loss altogether.

3. Rate-of-flow measurement by direct reading meters: For this method, the only suitable meters are direct read devices such as paddle meters, magnetic flow meters and other accepted process measurement instruments.

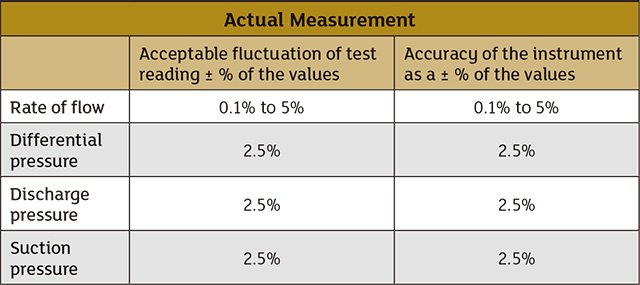

Table 1 shows acceptable fluctuations of test readings and instrument accuracy.

Table 1. Test reading fluctuation and instrument accuracy (Courtesy of Hydraulic Institute)

Table 1. Test reading fluctuation and instrument accuracy (Courtesy of Hydraulic Institute)Q. What is an appropriate way to determine the net positive suction head (NPSH) margin, and what factors should be considered?

A. The recommended use of the NPSH margin involves a known pump design having fixed NPSH3 characteristics that result in a reasonable and safe suction specific speed. In such a situation, users should apply the NPSH margin to the NPSH3 at the flow rate of interest to obtain the minimal value of NPSH available (NPSHA). The use of a higher value of NPSH margin in such a situation generally results in more conservative conditions for the pump. If the recommended NPSH margin cannot be obtained, choosing a lower operating speed for the pump for a fixed flow rate will generally result in a conservative selection.

Users should be cautious when obtaining NPSH margin by specifying pumps with higher suction specific speeds that have lower NPSH3 values. Higher suction specific speed pump designs are more likely to experience objectionable noise and a narrower operating range as compared with lower suction specific speed pump designs.

Extra margin may be necessary to account for changes in pump geometry that can increase NPSH3. For example, erosion can enlarge impeller running clearances and increase internal leakage at the impeller eye, adversely affecting the NPSH3.

Added NPSH margin may be needed either to cover uncertainties in the NPSHA or because of the actual operating rate of flow. If a pump consistently operates at higher than expected flow rates, then the NPSHA of the system may be lower than expected and the NPSH3 for the pump will be higher, providing a smaller—or possibly negative—NPSH margin.

Poor suction conditions may result in flow column separation and distorted flow at the impeller inlet, which can adversely affect the NPSH available to the pump. The negative effects of poor inlet/suction conditions are difficult to calculate. Greater NPSH margins might not correct the problem. Optimum pump performance requires users to follow proper intake/suction piping design to ensure a steady, uniform flow to the pump suction at the required suction head.

The determination of an adequate NPSH margin is dependent on an accurate prediction of both pump NPSH3 and system NPSHA. Factory NPSH3 tests can help validate the predicted pump suction performance. Determination of the NPSHA is the responsibility of the system designer.

For more information on net positive suction head, please refer to ANSI/ HI 9.6.1 Rotodynamic Pumps Guideline for NPSH Margin.

For additional information, refer to ANSI/HI 7.6 Controlled-Volume Metering Pumps for Test.