Because centrifugal pumps are widely used, pump and rotating equipment engineers are generally familiar with this equipment's operating principles, performance curves and selection criteria.

Image 1. While centrifugal pumps are the subject of much training, the dwindling population of reciprocating pumps has led to a loss of understanding of this pump type's unique system design requirements. (Images and graphics courtesy of Hydro, Inc.)

Image 1. While centrifugal pumps are the subject of much training, the dwindling population of reciprocating pumps has led to a loss of understanding of this pump type's unique system design requirements. (Images and graphics courtesy of Hydro, Inc.)While centrifugal pumps are the subject of much training, the dwindling population of reciprocating pumps has led to a loss of understanding of this pump type's unique system design requirements. Centrifugal pump specifications are now commonly and incorrectly applied to reciprocating pumps, which can lead to significant reliability problems.

End users should consider these 10 key facts about reciprocating pumps that can influence reliability and operation.

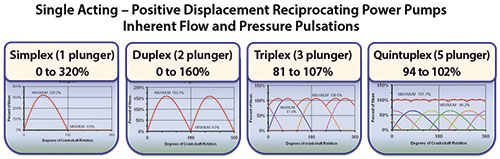

1. Pressure Pulsations

Unlike centrifugal pumps, reciprocating pumps have a stronger interaction with the overall system as a result of the pressure pulsations they generate. Because of the linear reciprocating motion of a plunger/piston, the plunger/piston velocity is zero at two points: the end of each stroke where the plunger/piston changes direction at the full forward and full reverse positions.

The pulsations generated by this varying velocity interact with the piping system and can be destructive. The pulsations are present on both the suction and discharge systems and can be mitigated by correct pump selection and the application of pressure dampening devices. Pump system analysis and modification can also greatly benefit pump reliability.

2. Performance & Speed

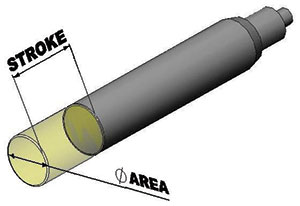

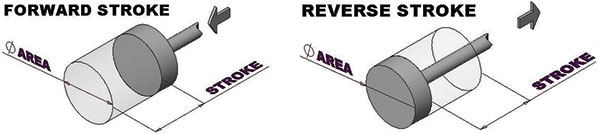

The flow of a reciprocating pump is determined by the fixed displaced volume inside its liquid cylinder and the rate (pump speed or rpm) at which the plunger/piston can move this fluid through the system. These are fixed-volume machines.

The easiest way to change the flow of a reciprocating pump is to change the rate at which the plungers/pistons move liquid through pump valves into the system. The performance curve of a reciprocating pump differs from that of a centrifugal pump. Closing the discharge valve increases the pressure but does not change the flow.

Reciprocating pumps run at a much lower speed than centrifugal pumps. By increasing speed, the packing and sealing life of the machine can be compromised. Balancing speed and plunger size can improve reliability and increase plunger and sealing life.

Figure 1. Pump flow and pressure curves

Figure 1. Pump flow and pressure curves 3. Packing & Sealing

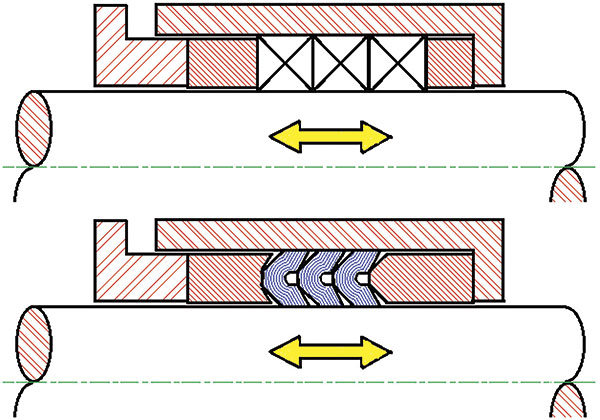

Reciprocating pump packing configuration, speed and plunger surface treatments influence sealing ability and the life of the packing and plunger/piston rod.

Plunger/piston rod packing in a non-lubricated stuffing box design relies on the pumped fluid to provide lubrication between the packing and plunger, which helps keep temperatures low. Modifying packing configurations and/or plunger coatings can considerably extend packing and plunger/piston rod life.

4. Efficiency & Performance

In general, a reciprocating pump is more efficient than a centrifugal pump. Reciprocating machines are generally applied on low-flow/high-head service. Centrifugal pumps can have efficiencies as low as 40 percent on low-flow/high-head service. A reciprocating machine can have efficiencies greater than 90 percent on the same service. Using reciprocating machines can help end users achieve considerable power savings.

5. Plunger Coatings

Hard coatings on plungers are applied to resist the wear caused by the linear motion between packing and plunger. While these coatings can be effective, coating technology has advanced rapidly, and new hard wearing materials can considerably extend plunger life.

Ceramic coatings that were once state-of-the-art can now be improved by the application of high-velocity oxygen fuel (HVOF) coatings. Ceramic coatings are hard but tend to be very brittle. In an industrial environment, this brittleness can result in damage during shipment, assembly or routine handling, which can lead to equipment failure.

6. Leakage to Atmosphere

Because of environmental emissions regulations, many reciprocating pump users are considering replacing their machines with diaphragm pumps. While reciprocating machines have a packing system that leaks, mitigating and collecting this leakage is possible and can allow the pump to meet environmental fugitive emissions regulations. Modifying stuffing box arrangements is much less expensive than replacing the machine.

Figure 2. Fixed displaced volume – single-acting pump

Figure 2. Fixed displaced volume – single-acting pump Figures 3 and 4. Fixed displaced volume – double-acting pump

Figures 3 and 4. Fixed displaced volume – double-acting pump Figures 5 and 6. Standard non-lubricated stuffing box designs

Figures 5 and 6. Standard non-lubricated stuffing box designs7. NPSHR

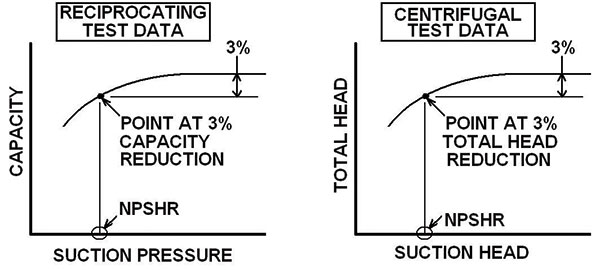

A centrifugal pump's net positive suction head required (NPSHR) is determined when the head has dropped 3 percent under reducing net positive suction head available (NPSHA) conditions.

For a reciprocating pump, 3 percent capacity drop is the criteria for defining NPSHR. NPSHA is reduced until the capacity drop has exceeded 3 percent.

The NPSH that was available at 3 percent capacity reduction is, by definition, established as the NPSHR.

A number of components can be modified to improve NPSHR. These modifications are much simpler than those required by a centrifugal machine.

Images 2 and 3. Ceramic plunger damage

Images 2 and 3. Ceramic plunger damage8. Belts

Many reciprocating machines still use drive belts over different diameter wheels to ensure that the speed of the machine is matched to the performance requirements. The type, number and fitting of the belts is important, and incorrect installation and application can cause failures.

Figures 9 and 10. Net positive suction head required determinations

Figures 9 and 10. Net positive suction head required determinations9. Viscosity

When dealing with high viscosity, reciprocating machines perform considerably better than centrifugal machines. Reciprocating pumps can easily handle highly viscous liquids, and this viscosity has little effect on flow rate, which is not the case with centrifugal machines.

10. Training

Centrifugal pumps are widely understood, and their applications are common. Reciprocating pump specialist training can greatly improve the understanding of these machines and help users improve their performance and reliability.