What is meant by the temperature class for my pumps that are rated for explosive atmospheres?

Pumps installed in potentially explosive atmospheres must be designed and operated in a way to limit their surface temperature based on the type of potentially explosive atmosphere. A reference for the requirements of electrical and nonelectrical equipment is the European Union (EU) ATEX Directive 2014/34/EU (Ex). Within this directive, one requirement is that pumps have a temperature class as stated in the explosion (Ex) rating on the nameplate. These are based on a maximum ambient temperature of 40 C (104 F). Refer to the manufacturer for higher ambient temperatures.

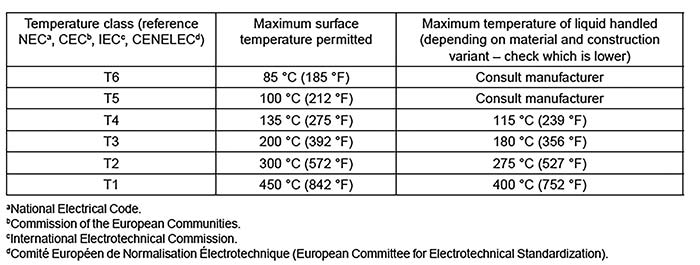

The surface temperature on the pump is influenced by the liquid handled. The maximum permissible liquid temperature depends on the temperature class and must not exceed the values in Image 1. The temperature rise at the seals and bearings due to the minimum permitted flow rate is taken into account in the temperatures stated.

Image 1. Temperature class, surface temperature and liquid temperature

Image 1. Temperature class, surface temperature and liquid temperatureNote that the plant operator is responsible for compliance with the specified maximum liquid temperature. Surface temperatures above 54 C (130 F) can cause irreversible skin damage and, therefore, require insulation to ensure personnel protection.

For more information about the manuals describing the installation, operation and maintenance of rotodynamic pumps, refer to ANSI/HI 14.4 Rotodynamic Pumps for Manuals Describing Installation, Operation, and Maintenance at pumps.org.