HI Pump FAQs is produced by the Hydraulic Institute as a service to pump users, contractors, distributors, reps and OEMs.

05/20/2015

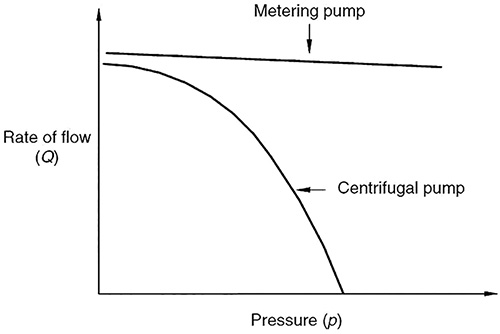

Q. What principles drive the pumping action in a controlled-volume metering pump? A. The pumping action is developed by a reciprocating piston. This reciprocating motion develops a flow profile represented by a sine wave. Actual rate of flow is determined by the following formula: Rate of flow = Displacement x Cycles per unit of time x Volumetric efficiency Figure 7.3.1a illustrates how changes in discharge pressure minimally affect the rate of flow from a reciprocating, controlled-volume metering pump.

Figure 7.3.1a. Rate of low versus pressure (Graphics courtesy of Hydraulic Institute)

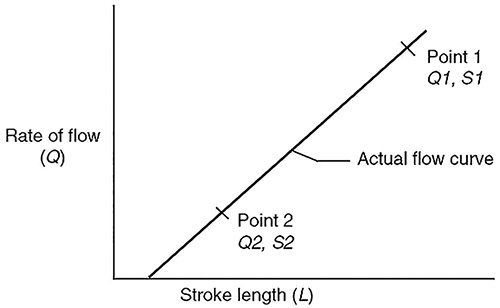

Figure 7.3.1a. Rate of low versus pressure (Graphics courtesy of Hydraulic Institute) Figure 7.3.1c. Actual flow curve, rate of flow versus stroke length

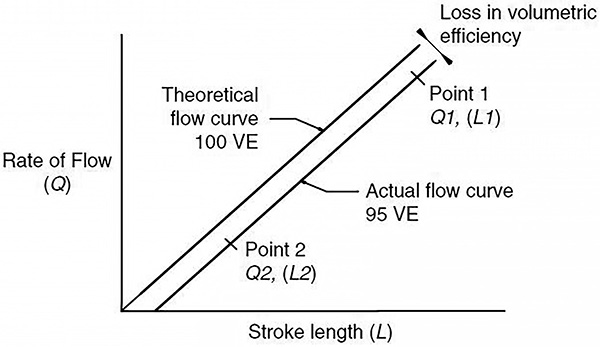

Figure 7.3.1c. Actual flow curve, rate of flow versus stroke length Figure 7.3.1d. Theoretical and actual flow curve,rate of flow versus stroke length

Figure 7.3.1d. Theoretical and actual flow curve,rate of flow versus stroke length- Emission control of process fluid to the environment under normal operating conditions

- Emission of process fluid under upset conditions or failure of the primary seal

- Acceptable life (time between repairs) as a result of inadequate lubricating properties of the pumped medium, which may be a result of too many solids too close to vapor pressure, too low viscosity in combination with pressure and speed, or too high pressure differential for one set of faces

- Dual pressurized seals can seal products that crystallize, burn or are otherwise unsuitable for single seals.

- Dual seals can limit loss to the atmosphere. This feature may be a factor in seal selection for equipment handling hazardous materials.

- Seal life may be improved as the seal faces operate in a clean, cool environment.

- Seal performance can be confirmed by monitoring the barrier fluid.

- The faces are lubricated using a clean, cool liquid—usually oil, water or glycol—which provides low wear rates.

- Dual gas seal faces are separated with a clear inert gas such as nitrogen.

- The seal operates independently from the pump. Consequently, loss of product, cavitations or other disturbances can be better tolerated.

- Zero emissions or product leakages are released into the atmosphere.